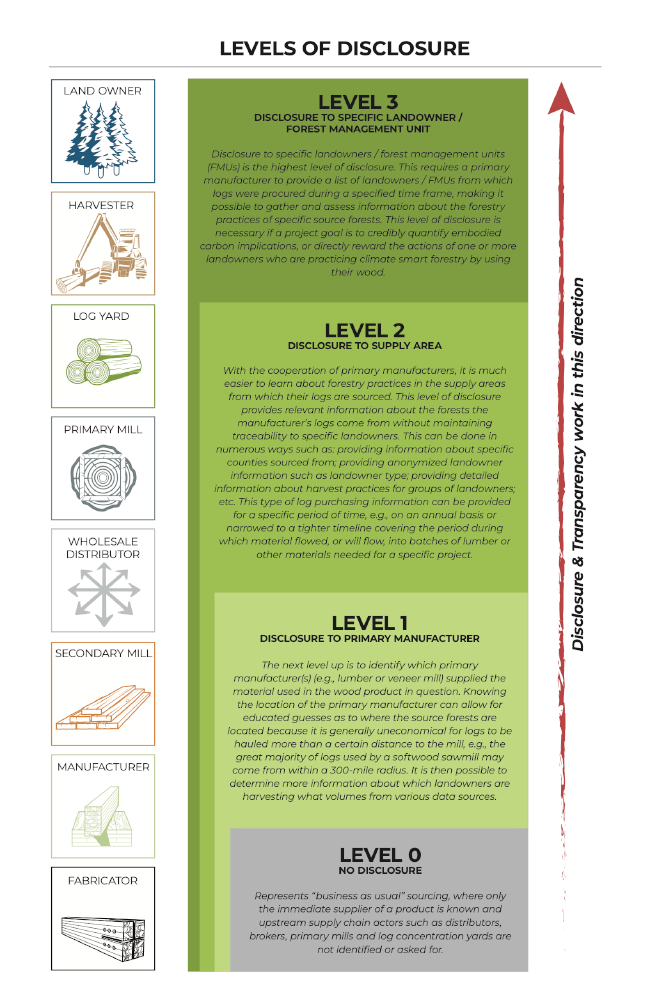

When gathering information on traceability and transparency, the project team can adopt an approach suited to the level of disclosure desired — back to the primary manufacturing facility (Level 1), to the log supply area (Level 2), or back to individual timber harvest units (Level 3).

Any information gathering methodology should address the following elements:

Numerous case studies are available to inform projects’ information gathering approach and learn from peer experiences. In addition, CSWG and its partners are in the development phase of specification language that addresses traceability, transparency and climate-smart forestry attributes. These are expected to be available for use on a pilot basis in early 2024, and CSWG is available for project consultations until specification approaches are ready for use.

Traceability information gathering involves asking suppliers about their capacity and willingness to provide information that allows for product traceability. Traceability is the ability to track backwards from an end product up the supply chain to a source forest(s) with known management practices. This is linked to supply chain mapping but focuses on tracing individual products or batches of product backward through part or all of a supply chain map.

A basic method for establishing traceability is through “Chain of Custody documentation”: a paper trail (invoices, bills of lading, etc.) provided by the product vendor that extends as far up the supply chain as possible. This documentation should be collected, reviewed and authenticated.

Another method to establish traceability is through lumber grade stamps that are placed on most softwood lumber products in North America. In addition to the lumber grade itself, these stamps identify which sawmill the lumber originated from. Having identified the originating facility, one can begin to gather information about the forestry in the surrounding area.

Many manufacturers – particularly primary manufacturers – have sophisticated internal traceability systems that can enable accurate tracing up the value chain to the forest source. These are the systems that enable them to internally track fundamental business and profitability parameters. Some companies might be hesitant to admit having traceability infrastructure for proprietary reasons, whereas others view their association with above-business-as-usual forestry as an asset to their business plan. Project teams should view themselves as a demand driver in the marketplace to draw out and partner with companies in the latter category.

In addition, commercial digital traceability systems (e.g., Sourcemap, SupplyShift, Global Traceability) are available that can be used to aid traceability, but to date they are not commonly used by the North American forest products industry. Digital traceability systems are also being used by some national governments to improve law enforcement and improve revenue collection in the forest sector, but not in the US or Canada.[1]

Finally, it is possible in some cases to use timber identification technologies[2] to identify the forest of origin for wood without knowing the full supply chain, but for a variety of reasons including cost and limited reference data, the use of these methods is currently uncommon. For all these reasons, the most practical way to establish traceability for wood products today is through Chain of Custody documentation.

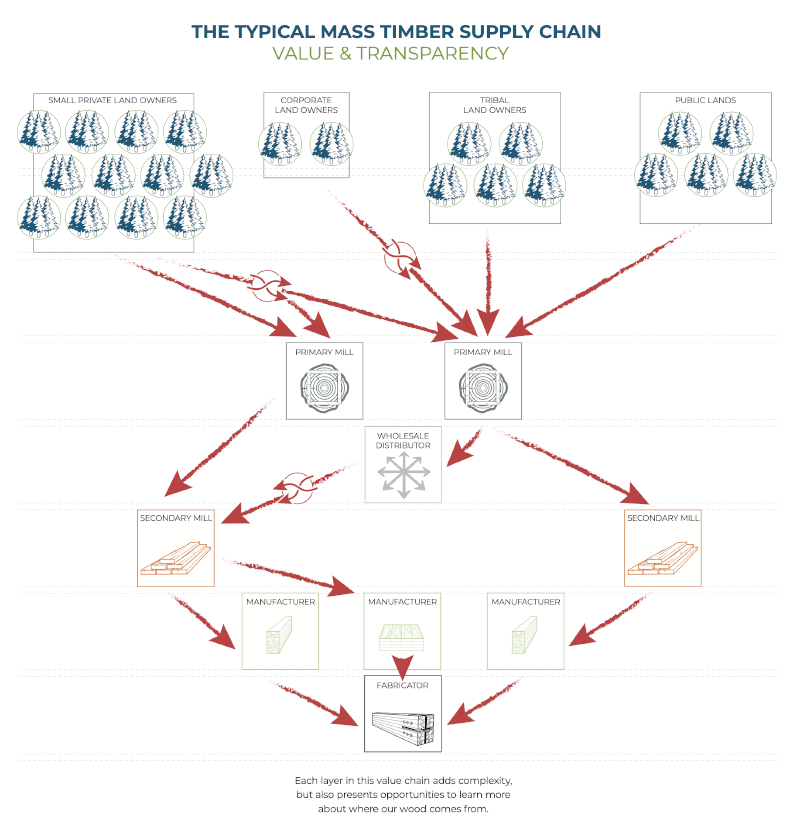

To provide transparency, suppliers can be asked to provide a schematic depiction of the supply chain links from forest(s) of origin down to the wood products they offer. If there are multiple products or source forests, there will likely be multiple supply chains. The ask for asensitive supply information is often best made by a vendor’s direct customer whom they may know well and trust instead of by a project team member they are less familiar with (or in tandem). It is likely that efforts at supply chain mapping will yield some but not all forest-of-origin information.

Suppliers can be asked to disclose information about the source forest(s) for the products they offer. This will allow the project team to assess which sources best match project goals and avoid sources that don’t. There are different levels and methods of disclosure:

The three different levels of disclosure can be achieved using a wide variety of techniques. The efficacy and efficiency of these approaches vary by project objective, procurement approach, source area, supply chain actors, and so on. Best practice is always to begin considering these options at the earliest possible project stage .

Design teams can work with the supply chain to simply ask for information about log purchases at varying levels of detail. This can be done with the right questionnaire, architectural specification and/or a reporting template, but most importantly relies on early engagement of and careful communication with the primary manufacturer and fabricator around goals and requirements.

Information could be gathered from the supply chain actors for wood used in the project; if third-party certification systems are utilized and manufacturers use credit (mass balance) systems, teams can also ask for the same kinds of information about the forests supplying the timber used to build credits. Either information source would represent credible information about what kinds of landowners and forestry the project supported.

Level 3 transparency generally requires segregating logs from certain sources and tracking them through normal or dedicated production runs. This requires enhanced logistics at the primary mill, so it takes the right partner, the right timing, the right size of job, financial incentives, and early engagement to make this happen. More vertically integrated or small-scale mills may be more suited for segregation due to more limited log sources. Segregation goes beyond obtaining a report of all potential forest sources for a particular batch of wood, and can increase precision in linking wood products back to specific forests that meet certain criteria.

Construction specifications that set disclosure requirements with accompanying fillable forms are emerging to help design and construction teams track wood back up the supply chain in alignment with these levels. One open source set of templates known as the Wood Transparency Tools have been designed to align with the Levels of Transparency listed above. These templates are freely available online for download and adaptation by project teams interested in learning more about where their wood is coming from.

©2025 Climate Smart Wood Group. All rights reserved. Privacy Policy