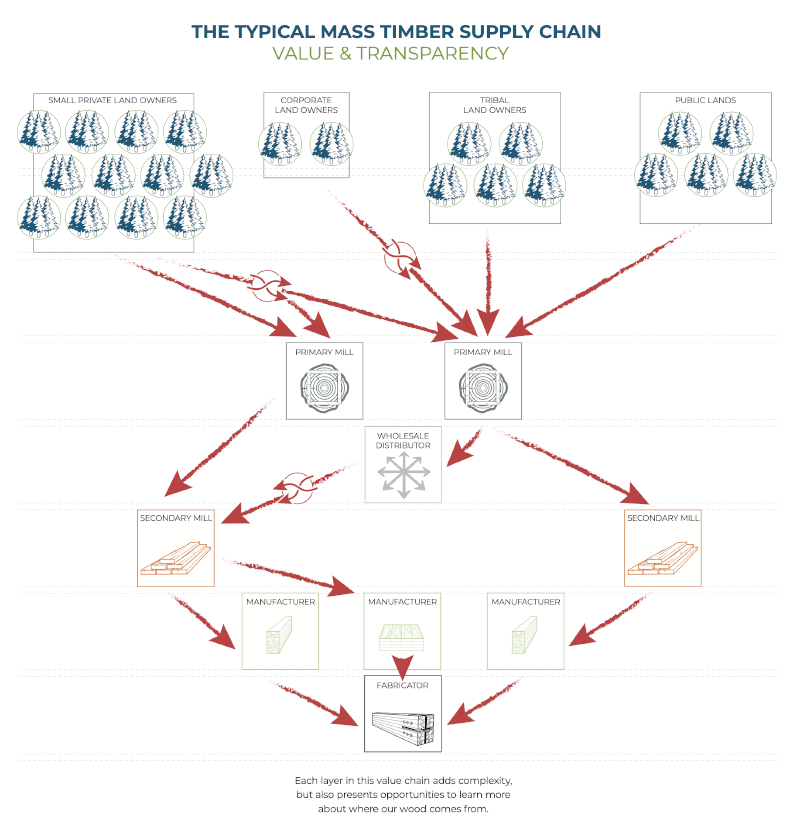

One major reason is mixing within the supply chain: it is very common for wood to be mixed at different stages of manufacturing and distribution. To take cross-laminated timber as an example, starting at the forest and working down:

This guidance is intended to provide the foundation for owners and the AEC community to consistently require transparency and traceability in their procurement. This can present some challenges that must be overcome, such as:

For all these reasons, project teams should be prepared to invest in traceability and transparency, and to reward suppliers for their cooperation, particularly when extraordinary efforts are needed.

[1] Note, however, that mills that focus on cutting higher grade lumber track individual log sources more often than mills focused on high production rates. For this reason, beams and wood used for lamstock offer a better opportunity for projects asking for segregation of logs from specific landowners than do mills cutting for standard dimensional lumber markets.

[2] Custom purchase of lamstock happens more frequently for large custom orders while production from inventory occurs more frequently at mills fulfilling smaller orders and commodity CLT dimensions. Options for custom purchase are often limited to known suppliers to reduce risks.

©2025 Climate Smart Wood Group. All rights reserved. Privacy Policy